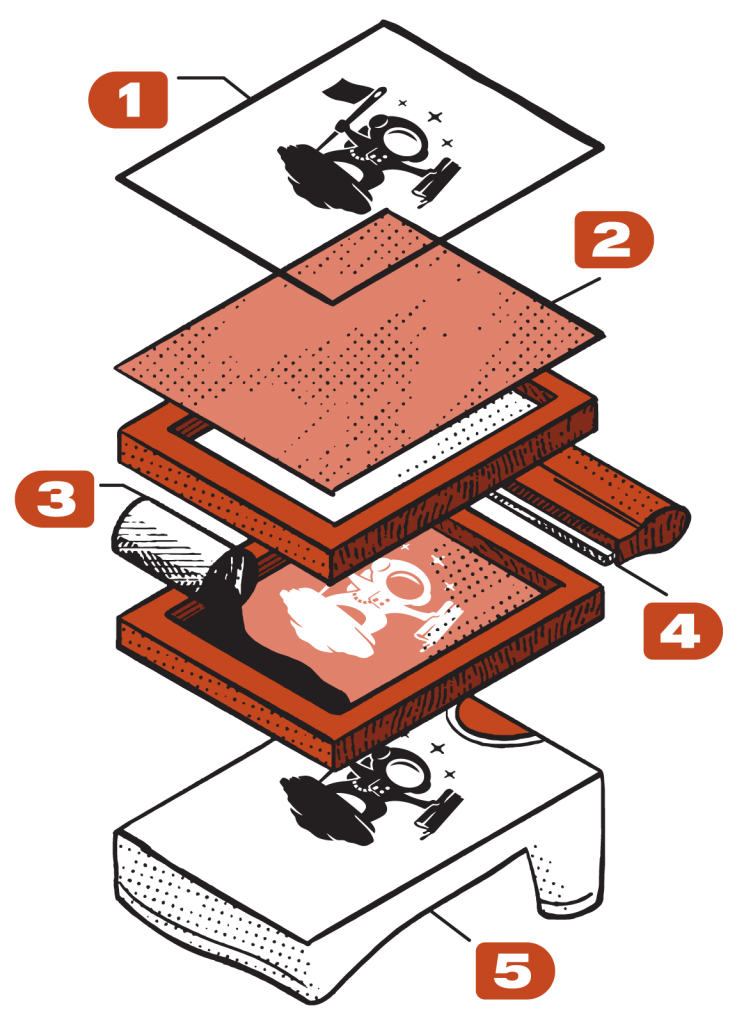

SCREEN PRINT

Ink + Mesh + Pressure = Beauty

Ever wondered how exactly ink gets transferred to shirts? Well let’s explain in a quick overview!

Up to 10 Printed Colors per Job

Industry-Standard Inks Available

Pieces per Day on Average

Production Working Days

Specialty Inks Available

Options Available